Instrument Introduction

This grinder is suitable for industries such as soil, geology, environmental protection, third-party testing, agriculture and animal husbandry, agricultural product quality, resources and environment. It can grind and analyze soil samples, heavy metals and other substances; Samples with different characteristics can be ground, including brittle, fibrous, medium low hardness, dry or wet grinding, etc;

Principles of Instrument Mechanical Processing: Impact Force, Shear Force, Friction Force

Instrument mechanical processing types: crushing, grinding, mixing, homogenization

Host parameters

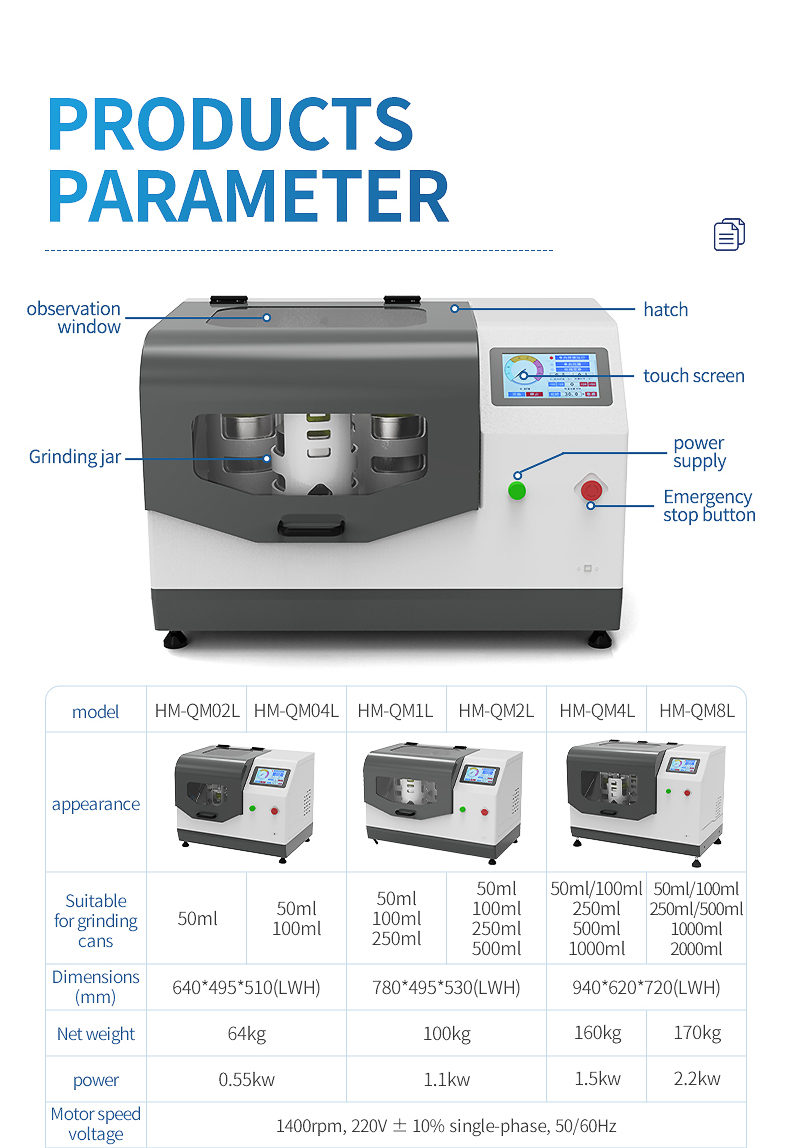

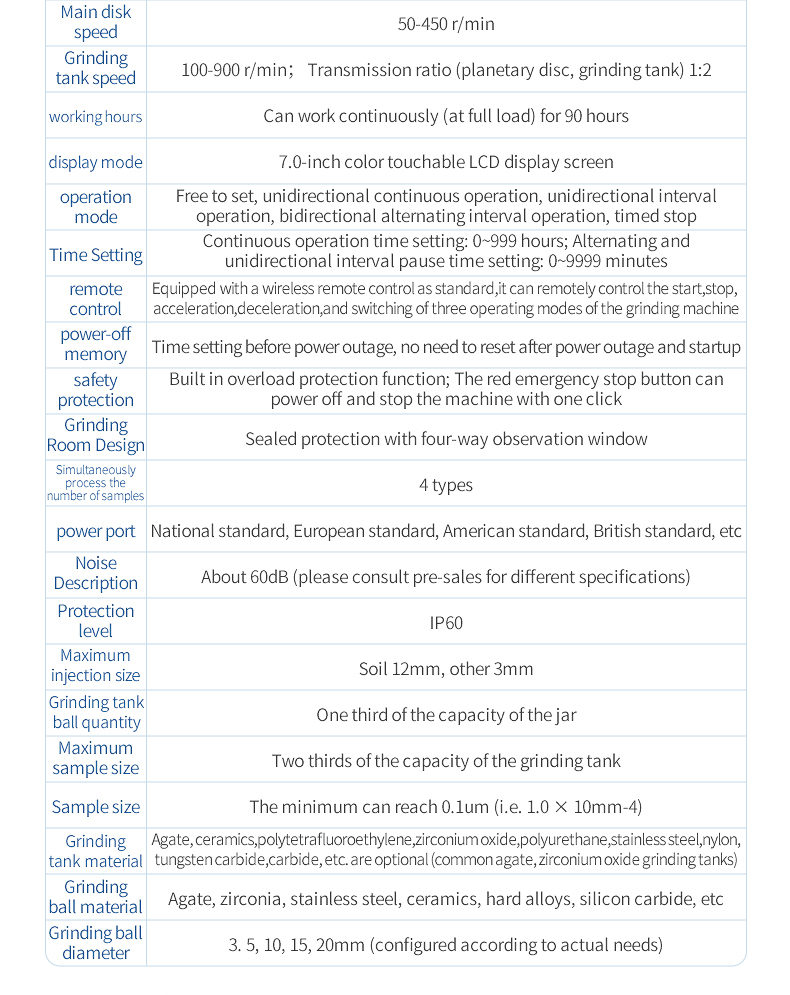

1. Main disk speed: 50-450 r/min

2. Grinding tank speed: 100-900 r/min; Transmission ratio (planetary disc, grinding tank): 1:2

3. Can work continuously (at full load): 90h

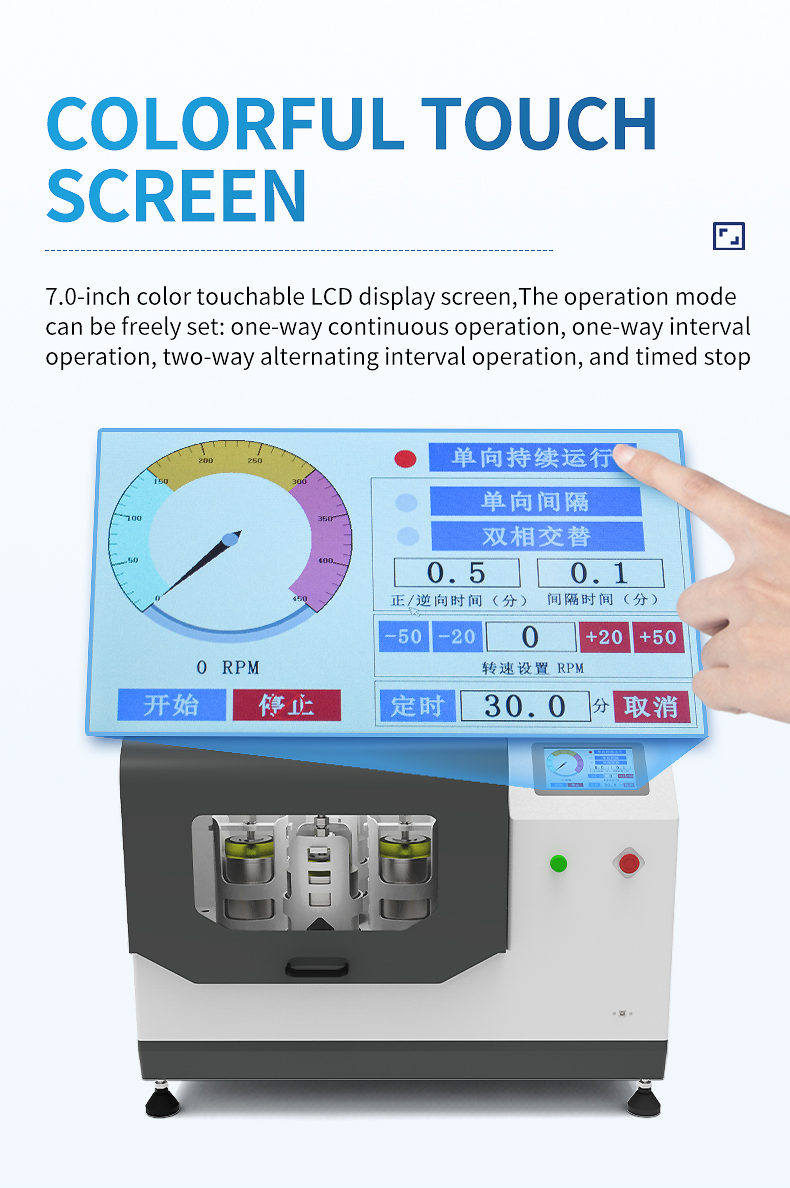

4. Display mode: 7.0-inch color touchable LCD screen

5. The operation mode can be freely set: one-way continuous operation, one-way interval operation, two-way alternating interval operation, and timed stop

Continuous operation time setting: 0-999 hours

Alternating and unidirectional interval pause time setting: 0-9999 minutes

6. Remote control: Equipped with a wireless remote control, the grinder can be remotely controlled to start, stop, accelerate, decelerate, and switch between three operating modes

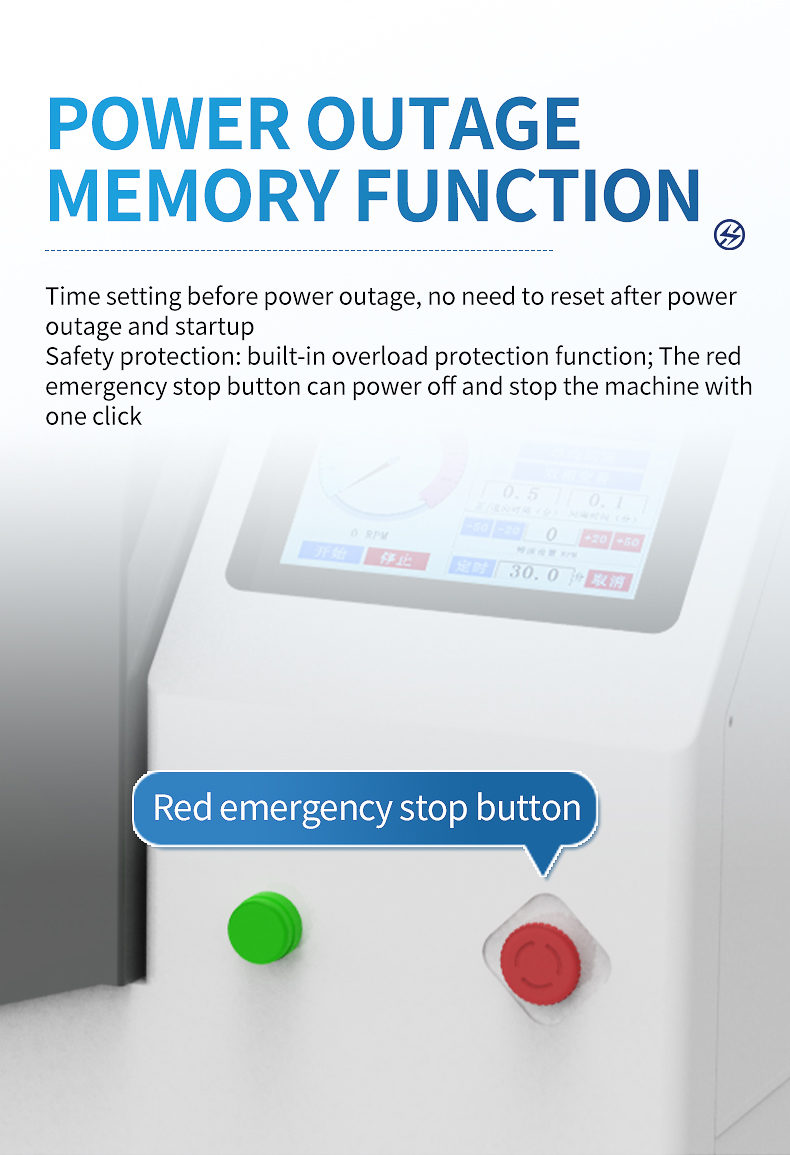

7. Power off memory function: Set the time before the power off, and there is no need to reset it after turning on the power off

8. Safety protection: Built in overload protection function; The red emergency stop button can power off and stop the machine with one click;

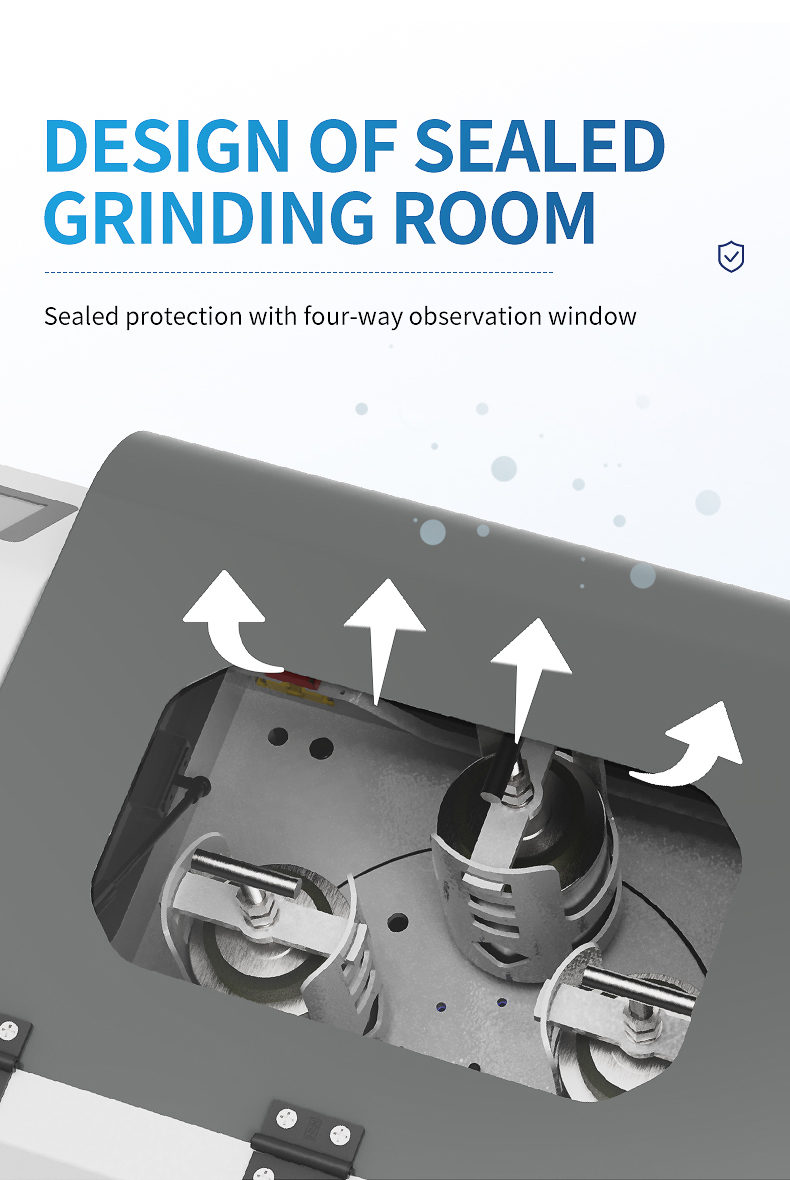

9. Grinding room design: sealed protection, with four directional observation windows

10. Number of samples processed simultaneously: 4

11. Power ports: National standard, European standard, American standard, British standard, etc

12. Motor speed, power, voltage: 1400rpm, 0.55kw, 220V ± 10% single-phase, 50/60Hz

13. Net weight: 64kg

14. Size: Length 640 * Width 495 * Height 510

15. Noise Description: Approximately 60dB (For different specifications, please consult pre-sales)

15. Protection level: IP60

Match grinding tank

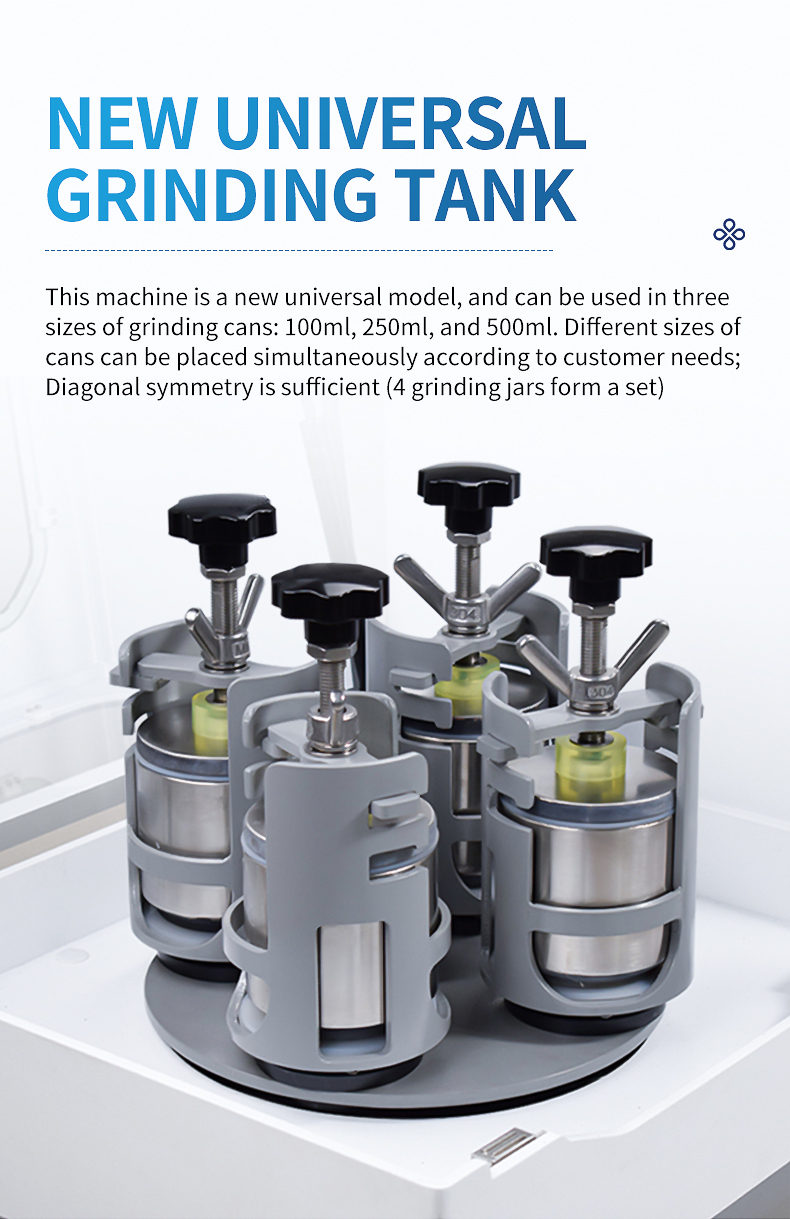

1. Applicable grinding tank: This machine is a new universal model, with a 50ml specification grinding tank. Different materials of grinding tanks can be used according to customer needs; Diagonal symmetry is sufficient (4 grinding tanks per set).

2. Maximum injection size: soil 12mm, other 3mm

3. Grinding jar ball quantity: one-third of the jar volume

4. Maximum sample size: two-thirds of the capacity of the grinding tank

5. Sample size: The minimum size can reach 0.1um (i.e. 1.0 × 10mm-4)

6. Grinding can materials: agate, ceramic, polytetrafluoroethylene, zirconia, polyurethane, stainless steel, nylon, tungsten carbide, hard alloy, etc. are optional (commonly used agate and zirconia grinding cans)

7. Grinding ball materials: agate, zirconia, stainless steel, ceramics, hard alloys, silicon carbide, etc

8. Grinding ball diameter: 3, 5, 10, 15, 20mm (configured according to actual needs)

Article address:https://www.soiltesting.cn/pro23/110.html

- Previous article:no more

- Next article:Planetary Ball Mill

+86 17853698681

+86 17853698681